FOR IMMEDIATE RELEASE

Conjectural Technology Laboratories announces breakthrough grape variety that produces intense colour effects in wine

By Fal Ernian, Vinotas News Service

April 1, 2018

British Columbia, Canada – Conjectural Technology Laboratories, a division of Tim Vandergrift Consulting and Communications LLC has released a wine based on a new grape variety genetically designed to produce a novel colour effect.

The grape variety is a cross between Sauvignon Blanc and another non-grape fruit, Pollia Condensata, commonly called the Marble Berry.

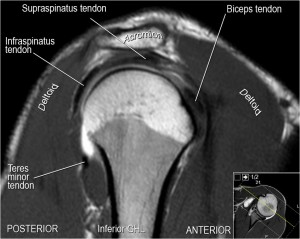

Back in 2008, Conjectural Technologies’ lead scientist, Professor Corey Irwin was looking at the reflectivity of wine grapes when he accidentally included a sample of the tropical plant in his magnetic resonance cylcotron.

“Frankly,” says Professor Corey, “They were part of a table arrangement in my office that caught in the sleeve of my lab coat. I didn’t notice them because the berries are tiny and the colour is so strong that they don’t actually look like real fruit, more like crazy ball-bearings.”

But the results from the test showed otherwise, and the fruit’s surface reflects nearly 50% of the light that hits it–vitis vinifera grapes reflect between one and two percent–due to the surface composition of the skin. “It’s as though the fruit is composed of nothing but tiny little mirrors, all over it!” explains the Professor.

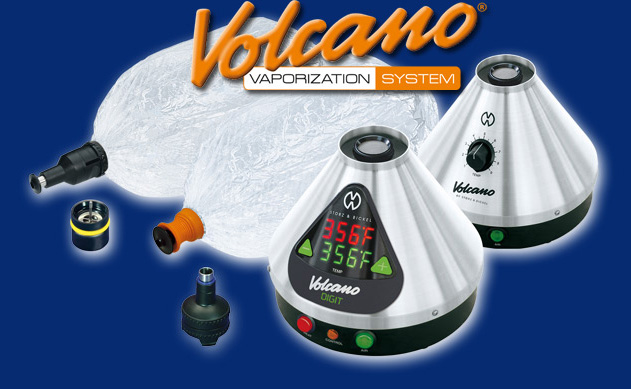

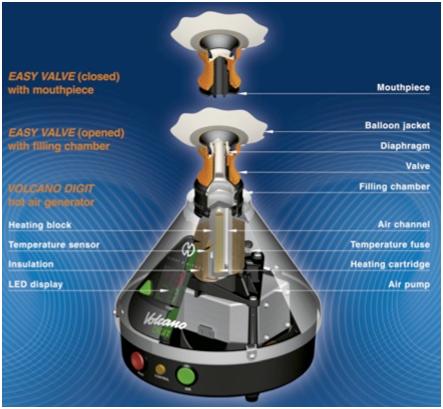

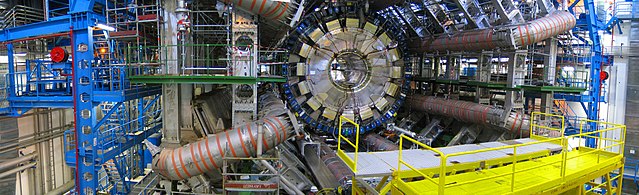

Sensing the potential for a revolution in the appearance of wine, the team at Conjectural Technologies launched into a genetic cross-breeding program, using Crispr-Cas 9 genome editing technology. With CRISPR (Clustered Regularly Interspaced Short Palindromic Repeats) “spacer” sequences are transcribed into short RNA sequences capable of guiding the system to matching sequences of DNA. When the target DNA is found, Cas9 binds to the DNA and cuts it, activating the targeted gene.

There were some early issues with genetically modifying fruit with this technique, but eventually the lab overcame them.

Chief Disruption Officer and Lead winemaker at TVCC-Kitworld, Tim Vandergrift is delighted with the results.

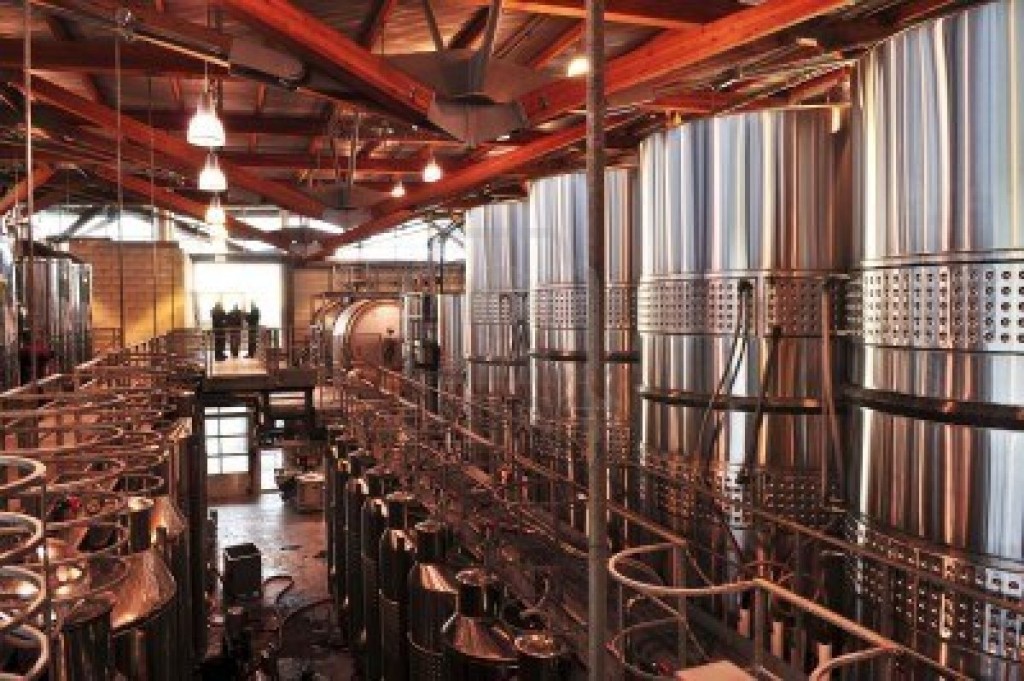

“This is a real game changer. For thousands of years wine has been red, white or pink. Well, brown too, if you forget and leave the top of the fermenter open. But now we have the ability to change its colour, not with dyes or pigments, but with the harnessed power of quantum physics and Genetically Modified Organisms!. By using gene editing and forcing together the sequences of pollia with Sauvignon Blanc and certain key sequences of hagfish and African land snails we were able to produce a grape that not only reflects more light, but has the viscosity to hold the reflectivity in suspension, so it doesn’t just fall out during fining, or settle on the bottom of the glass.”

Vandergrift admits that the wine is slightly different from standard grape wines, including a textural change. “The hagfish and snail genes are there to provide a colloidal gel that keeps the reflective particles from binding to anything else. It does make the wine viscous, but it’s not too gooey–it has exactly the same viscosity as transmission fluid, and once you get used to it, it’s really nice.”

The new wine, tentatively called ‘Quantum White’ will be available for commercial release on April 1, 2019. Expect it to be in high demand, as in addition to providing a pleasing flavour and aroma, it is expected to be an excellent substitute for Dexron III transmission fluid.