- Is the grape juice concentrated, reduced or pasteurized.?

- What type of chemicals are added?

- Is the grape juice concentrated, reduced or pasteurized.?

- What is the juice in the kits treated with?

- Are there any unfermentable sugars added?

- Is it ok, instead of filling up to 6 gallons to fill up to 5, to make it more flavorful?

Oregon Dave,

Thanks for writing–all good questions and since you’ve made wine, you’re not a ‘wannabe’. You’re part of the family of people who make and enjoy wine–and nerds are our favourite!

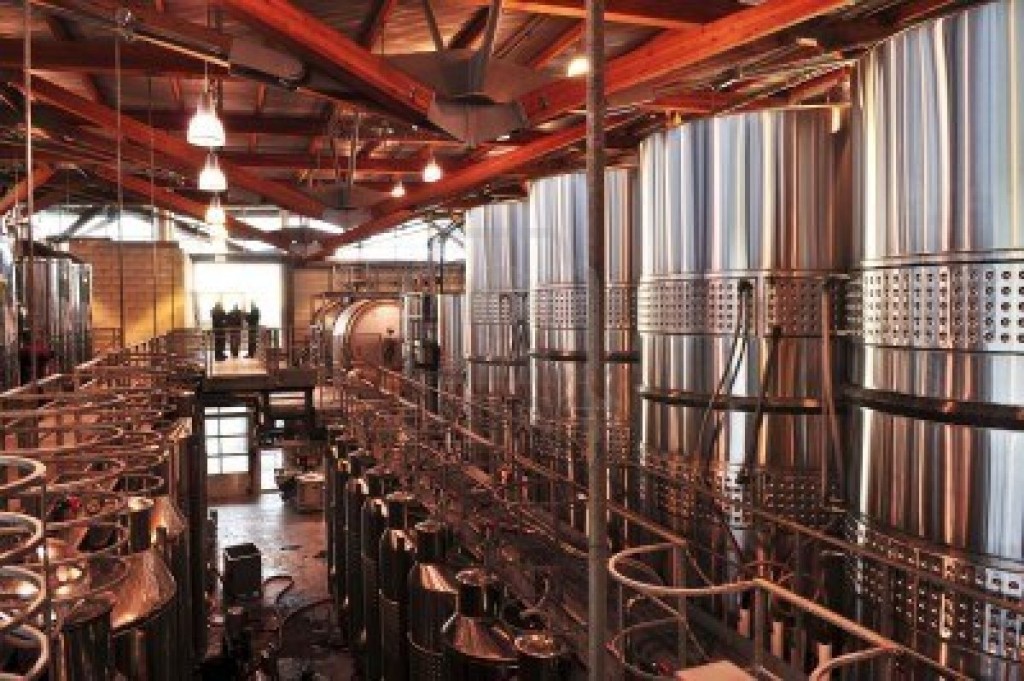

Master Vintner kits are made from a blend of concentrates and fresh, single-strength juices. Keep in mind that the concentrates themselves are made from single-strength juice that has had the water removed through one of the common concentration processes

- Vacuum distillation

- Reverse Osmosis

- Spinning cone

Different producers use different processes, but all come down to carefully removing the water without stripping the flavours and aromas of the juice.

There are a couple of good reasons to use concentrate in a kit, and one very important one.

- Concentrate weighs less and ships lighter than single-strength juice. That saves money not only on the front end, when we buy our raw materials, but also on the back-end when we ship it to you.

- Concentrate is shelf-stable at room temperature. With the high sugar level and extremely low pH, it doesn’t allow spoilage organisms to grow, and is very resistant to oxidation.

- Most importantly, that low pH/high sugar effect carries over when concentrate is blended with the juice. Fresh, single-strength grape juice can’t be held or shipped at room temperature, and even at refrigeration temperatures (4-8C/36-40F) it will still spoil in only a few weeks. But if you blend it with concentrate to a minimum specific level of sugar and pH, it will last 12-18 months on a shelf. Concentrate is what makes wine kits possible!

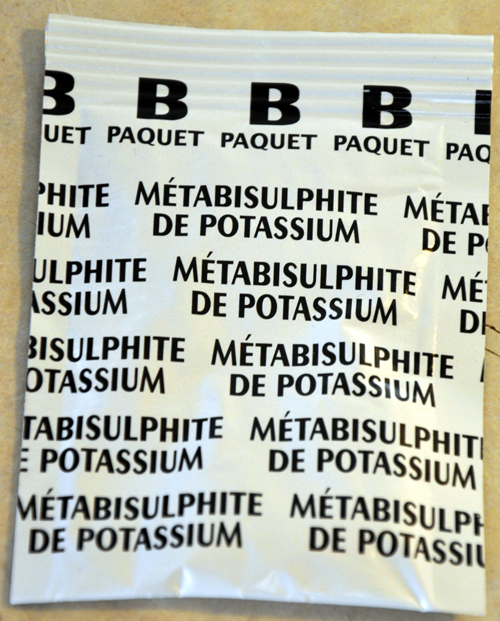

Once the juices for the kits are assembled (blended, adjusted for acid and pH, etc) they are flash pasteurized and sterile packed. This process involves heating the juice to 70-82C (160-180F) very quickly, then cooling it to room temp again, all within a cycle of under 90 seconds. After that, it’s weighed out into sterile bags and capped. Other than very low amounts of sulfite, no other chemical additives are used.

Juices aren’t treated with anything that isn’t already in use in the commercial wine industry. They can be amended with grape acids (tartaric and malic acid) or tannins, but that’s it.

It’s very rare for wine kits to use any added sugars: they don’t integrate well into the flavour profile if used in any quantity, but if they are needed to boost ABV in the finished kit, it will say so on the label on the side of the box.

Unfermentable sugars, such as lactose, are not used.

It is very specifically not okay to make a kit to 5 US gallons (19 litres) rather than the specified 6 gallons (23 litres). That will throw off the acid, pH and flavour profile completely, and it’s kind of like making your frozen concentrated orange juice up with only two cans of water instead of three: is that better orange juice, or just a thick glass of acid, too-sweet goop?

If you want to boost the character of your wine kit, buy one of our premium kits, like Sommelier Select, which contain more, and more expensive-to-source juices. They’re not ready to drink as early as the smaller kits, but after a few months, You’ll see where the extra money went–into higher-cost, higher-demand juices that cost more to use. Rather than cut down your yield by 25%, spend 25% more money, get your extra six bottles and delicious wine to boot!

Thanks for writing Oregon Dave. I hope this helps out, and wish you many years of happy winemaking!