Grinding Away

I don’t always drink wine. Or even beer. I don’t even drink whisky every day, come to think of it. I don’t like soda pop for the most part, and I drink about two quarts of milk per calendar year. There are only two beverages I consume on a daily basis: water, of course, since I am a squishy bag of mostly water by design, and coffee, because it is delicious brain juice that lets me function in society.

I started drinking coffee quite young. In retrospect, being in the single digit range for birthdays was probably a little on the youthful side for drinking caffeinated beverages, but if you believe the Coffee Achievers, it was probably the making of me, and there are worse habits.

My taste in coffee has evolved over the years, as has the way I consume it. As a kid I liked it with lots and lots of milk and sugar. I lost my taste for sweets after a while, quit bothering with milk, and started drinking hot, black coffee by the gallon. Keep in mind I was raised by simple prairie folks, and the coffee wasn’t premium or sophisticated. It was pre-ground, canned coffee that was on sale, and made in an automatic drip machine manufactured by a company more known for electric drills and sanders than for food equipment.

A friend of mine once described this beverage as ‘Lutheran Coffee’, after the kind of brew you find in one of those giant percolators in a church basement. I liken it to hot brown coffee-water. After I left home I started buying beans and getting them ground at the store. Then I bought my own grinder, and one of the most perfect coffee making machines ever invented: the Melitta Cone Drip. That worked for years, until I got a bug in my ear about espresso. Then I had several set-ups, refining how I like my coffee with automated espresso makers, stove top units, et cetera.

I keep experimenting with coffee making, but the final frontier for me has been to seize control over roasting my own beans. Coffee is the seed of a cherry-like fruit, and after gathering and processing, it looks like a little green rock with a cleft in it, and it doesn’t taste of anything special. It’s not until you roast it to a rich, chocolatey brown that it releases that heavenly aroma and beguiling flavour.

By this time you should be getting the idea that I never leave well enough alone, and everything in my life is in imminent danger of becoming an obsession. I did some research, fiddled around a bit with primitive methods, including roasting beans over a wood fire in an iron pan like the Ottomans did, but a conversation with a professional coffee roaster made me realise that there was something to having the right piece of equipment for the job: heat ramp-up especially was a thing. There’s a long explanation, but if you heat the beans up too slowly they dry out and lose some of their nuance. Heat ’em up too fast and they just char instead of roasting nicely. A good roasting machine can take that into account. A good machine like the Behmor 1600.

The unit is a masterful design. You can check out the manual here, which is an excellent segue: always read the instructions. With some things, like an ice-cube tray, the stakes are low. If you do it wrong, worst-case, you don’t get ice cubes. Because this machine is using high heat to dry out and subsequently roast cellulosic vegetable matter saturated with oil (coffee), if you overdo it, it can catch fire. Which is bad.

If you’re going to get a roaster, read and pay close attention to those instructions. They’ll make sure you stay safe and that you get a decent cup of coffee from the first try. After that, you can start fiddling around with the time, ramp-ups, drum speed and all that jazz. But start with the basics. To show you those basics, have a look at this overview of roasting basics that I put together in my kitchen.

The manual may be a little intimidating at first, but as you can see, it isn’t rocket surgery: Follow the instructions, don’t leave the Roaster unattended while it’s on, and learn to recognise the difference between first and second crack and you’re in.

If you’re curious about the coffee making rig shown at the end of the video, it’s an Aeropress, and it’s what I use to make an excellent–just about the best, really–cup of hot coffee I’ve ever had.

But what if you want a bigger thrill? What if you want the ultimate in coffee deliciousness? What if you want . . . this

Cold-brewed coffee is the hottest-cold thing to show up in coffee use in the last ten years. You get flavour extraction by trading the heat of the water for time. Rather than a three or four minute steep with water around 200F (your mileage may vary) you use tepid water and soak overnight, or for 24 hours. This slow, gentle extraction leaves behind a lot of the harsh tannins, while teasing out the smooth, rich flavours that make coffee so wonderfully good.

And Nitrogen dispense is what has made Guinness Stout so popular. Forcing your cold-brewed coffee through a Stout Faucet with medium-pressure nitrogen gives it that creamy, foamy ‘cascade’ of flavour goodness. Honestly, it makes coffee wickedly drinkable, to the point where I have to monitor my intake or I’ll wind up dancing around like wacky waving inflatable arm flailing tube man.

Previously, if you wanted to do nitrogen dispensing at home, you needed a full-on setup, with a keg refrigerator (standard homebrew kegs are not fridge-friendly: they crowd out the pot roast), a nitrogen tank, special regulator, and a bunch of other bits and bobs. Not a stretch if your life includes that kind of thing as a hobby, but a bit of a stretch for your average coffee fan.

Enter the Jacked-Up™ Nitro Fully-Loaded Cold Brew Starter Kit. It includes everything you need for cold-brewed, insanely delicious cold-brewed-nitro-coffee at home. Two things make it ideal for home use. First, the keg itself. Have a look at mine.

Pop the tap and the regulator off of it and the whole keg fits onto a shelf in a standard fridge, ready to dispense your coffee at any time. (Don’t tell anyone I told you, but it’ll also dispense Wine like a champ).

Second, check out that regulator, with the attached nitrogen cylinder. You don’t need to buy the full-meal-deal nitrogen tank, regulator et cetera, you just screw in a cylinder of nitrogen gas, pop it on the keg and dial up your pour. You can even take the Cannonball keg with you to parties or the back yard, or wherever. This is a brilliant enabler of coffee usage.

Check out how I do it.

I’ve nearly got the whole coffee thing handled. Five, six more years at most and I’ll have my system perfected.

Now, I wonder how you roast your own tea?

The Word of the Day is ‘Spunding’

I know a little German . . .

I’ve been incredibly busy with my Master Vintner project–have a look at some of the things we’ve got going on over here–making wine, tasting wine, talking about wine, and generally loving the whole Master Vintner concept.

In all my time in the consumer wine kit business I wanted to make a kit that I was completely responsible for, not so much because I’m a shiny-eyed control freak, but because I wanted to share something where everything was done exactly the way I wanted it, at each step. I get to do that now, and it’s a rare privilege in business to make something this good, and then to see people making the kits and loving them.

But, I do have other interests–cooking, gardening, photography, travel, motorcycles, hunting, shooting, hiking, reading and generally messing around learning stuff, and, as it happens, suddenly going into deep geek mode when something catches my imagination (I have been accused of having ‘Attention Surplus Disorder’).

Which leads me to one of my latest offshoots: I was doing research on the Charmat Method, a process for making sparkling wine in pressure tanks, rather than carbonating in the bottle. It’s an interesting compromise: force carbonating, like the way they get the fizz into most mass-market beers, leaves large bubbles that are described as ‘coarse’, but it’s very inexpensive to do. Bottle conditioning is the traditional method for making champagne, and it uses a dose of sugar and yeast inside a sealed bottle to produce carbon dioxide in situ. That makes for fine, creamy bubbles, but it’s expensive and time-consuming. Do the conditioning in a tank and bottle it from there the theory goes, and you’ve got a decent product at a reasonable price.

The thing is, letting yeast have their way with sugar in a sealed vessel is tricky. Most homebrewers have had, or been present for a ‘bottle-bomb‘, where the carbonation was so high that either the bottle gushed foam like a fountain as soon as it was opened, pouring out until it was empty, or it actually exploded right where it was sitting. Glass is not a flawless choice for pressure applications.

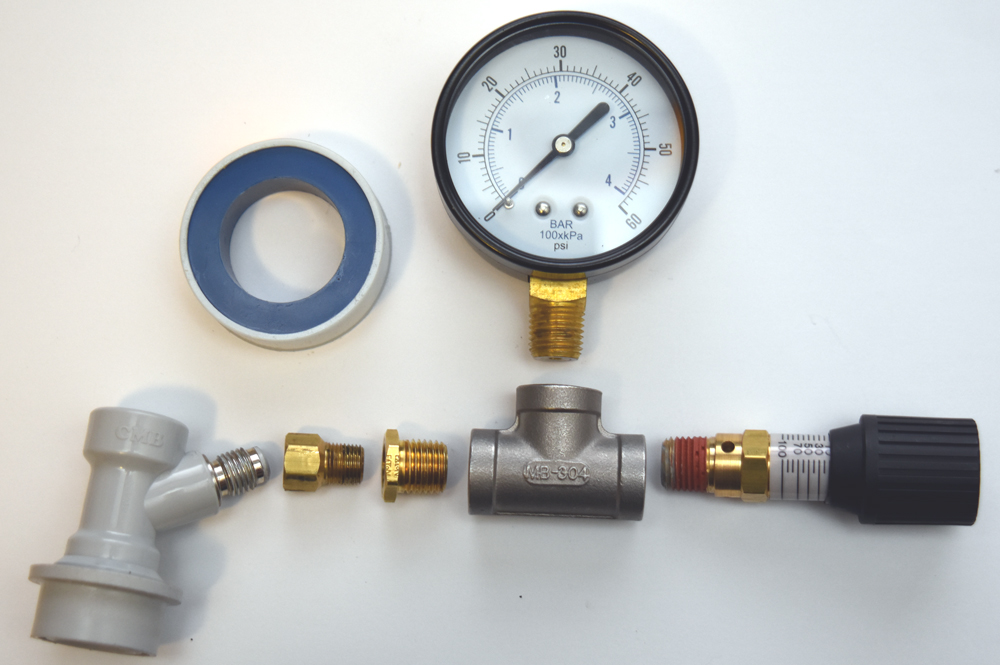

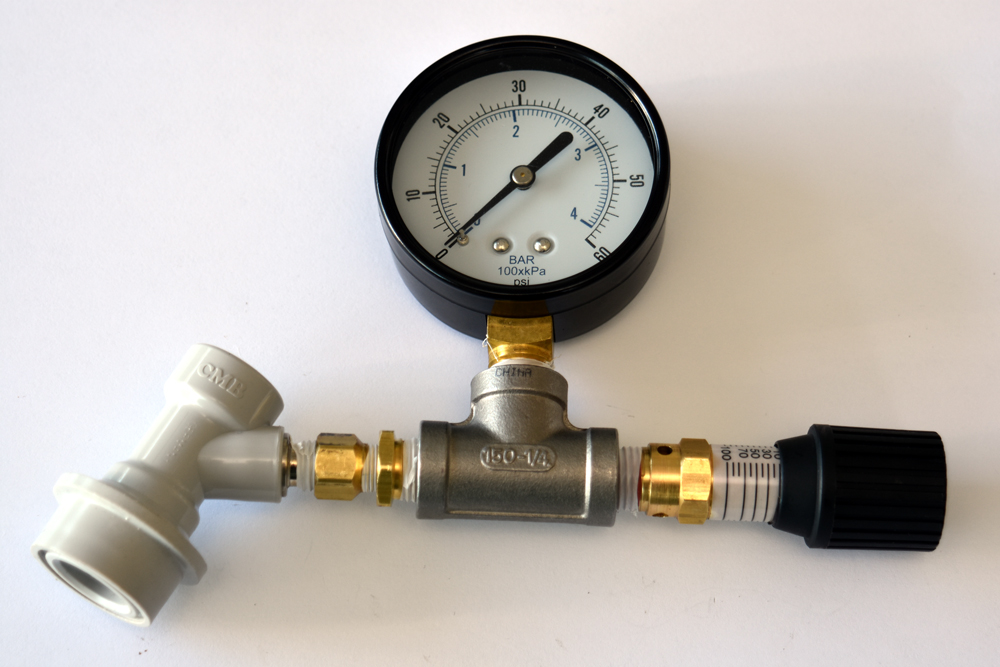

Stainless steel tanks are pretty good, but past a certain point, unless they’re built like scuba tanks, they’re nearly as dangerous as a bottle bomb going off. What you need is a pressure relief valve that you can set accurately to hold in the amount of pressure you want, but will vent anything past that. Sounds easy, and it is, if you’re a gas-fitter or a millwright, but for home beverage applications those things aren’t just lying around.

Except all the bits are there, right in front of you, if you speak German.

A Spundapparat is a pressure relief valve used in the process of krausening (those wacky Germans, it’s like they have a word for everything!). Krausening is exactly the same process as the Charmat method, but more German and less French. Tootling around on the internets gave me a good idea of what the deal was: while the classic use was krausening, spunding valves are also used to ferment beer under pressure, allowing beers to finish faster while producing fewer off flavours and undesirable characters.

I didn’t have any appropriate candidate wine for a Charmat process on hand, but I did have access to a sample of WLP 925 High Pressure yeast, designed to be fermented at 14 PSI, and the ingredients for a Pre-Prohibition Pilsner on hand (didn’t know I made beer? Well, it’s yet another hobby . . .)

A beer? A pressure yeast? An interesting apparatus to play with? What ho! In geek heaven, I hatched a plan and immediately launched it!

And then I immediately stopped because the parts I needed for the spunding assembly wouldn’t arrive for a couple of weeks. Poo. I put out a call to my brewer friends and one of them came through for me. Nathaniel lent me his spunding rig, which he used for transferring beers in his solera (it has to do with soured beers, a fad I’m hopeful will soon go away). His rig lacked a proper pressure gauge, but it wouldn’t be mission-critical in this application–the pressures were pretty low and I could fiddle around a bit.

Here’s his rig, and a tricksy little blow-off hose I rigged up. I’ll explain that in a second.

Attached to my blow-off keg (see below).

Here’s why the funny transfer hose: the grey disconnect is a gas-in connector. The black is a product-out connector. Product-out posts on the kegs have a stainless steel tube that runs to the bottom of the keg, allowing the liquid inside (wine or beer) to flow upwards, through the tap, into your glass, while the gas-in posts end right at the top of the keg. Makes sense, right?

I got a second keg, and set the whole thing up as a blow-off vessel. The very cool and complicated keg on the left is a Big Mouth™ Modular 5 Gallon Keg. Not only does it go from 1-gallon to 5 gallons with a few turns of a wrench, but also it has a port on top that allows you to hang an oak stave from (and retrieve it at will!) or a dry hop bag to flavour your beer. It’s my favoritest thing right now.

In case any foam-up during fermentation would flow through the gas port and travel down the product port in the smaller keg. Both kegs were sealed and purged, the spunding valve set at 14 PSI and the yeast was pitched.

It worked like a charm. The beer fermented dry in five days, and I heard the faintest of muttering from the valve as it uh, passed gas. I moved it to my keezer (keg refrigerator made from a converted deep freeze) to drop the yeast and chill down. The beer is quite good, but the yeast is non-flocculent (it doesn’t want to settle down). It’s not a huge flaw, but next time I’ll filter it to make it shiny and bright.

Now I had all sorts of ideas. My last round of winemaking with my Winemaker’s Reserve kits had me kegging a lot of them, in accordance with Vandergrift’s Second Principle of Winemaking (A winemaker’s desire to bottle wines is in inverse proportion to the number of bottles they have filled in their lifetime). In fact, I had a few kegs in the back of my car . . .

I wanted to do a pressure transfer of wine from one of my 10 US-gallon (38 litre) kegs to my awesomely excellent Master Vintner® Cannonball® Wine Keg System and the spunding rig would allow me to do a transfer under nitrogen gas, slowly and carefully. All I had to do was rig up a product-product transfer hose, attach a gas line between the big keg and the Cannonball, attach the spundapparatus to the Cannonball gas out, and then slowly dial back the spunding pressure and it would transfer meek as a mouse.

But I wanted a more accurate pressure gauge. the little direct rig was fine, as far as it goes, but I didn’t really trust it to be accurate. Fortunately, by now all of my parts had arrived, and I put my own special rig together.

It worked like a charm! Not only did I transfer wine from one container under inert gas to another, but also I did it without racking or pumping. A professional brewer or winemaker would be rolling their eyes at this point, as both of these are standard operations in the industry, but for a home winemaker it’s a pretty cool step, and it only cost around 25 bucks plus some Teflon tape.

What’s next for my little rig? I think it’s time to grab a Winemaker’s Reserve Pinot Grigio and do a Charmat-process sparkling wine–with good management and a little work I should have it ready to drink by the holiday season this year!

Unless, of course, I get distracted and do something even weirder in the meantime. I’ve been meaning to make a high-gravity Belgian beer with Muscat grape juice in it . . .

Announcement: New Kit Facility For Tim Vandergrift

FOR IMMEDIATE RELEASE

Tim Vandergrift Announces New Wine Kit Production Facility, KitWorld Inc.

By Fal Ernian, Vinotas News Service

April 1, 2016

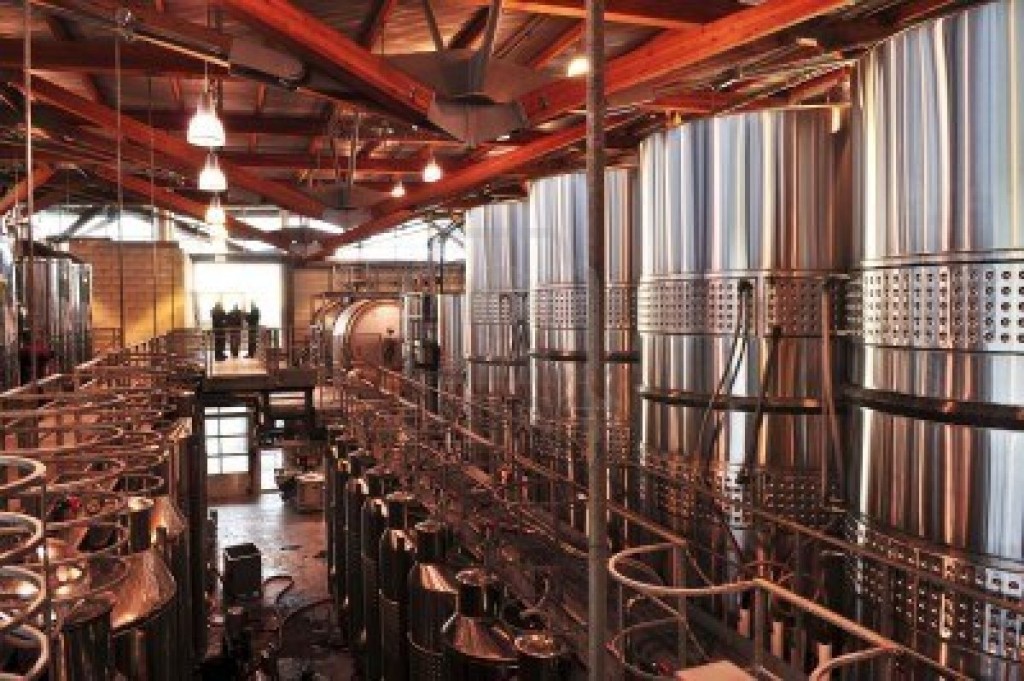

Modesto, Ca – Canadian company Tim Vandergrift Consulting and Communications Inc. announced today that it has finished construction on a 200,000 square foot processing facility for grapes, juices and concentrate, and will be releasing its new wine kits this month.

Construction of the facility, underwritten by private equity firm Lord-Buckley Capital, began in 2014 and final inspections and certifications were completed in March, during which a test run of thirty thousand kits was processed. Officials in the California Department of Food and Agriculture have certified the facility as fully operational and KitWorld Inc. goes into production today.

TVCC expects this facility to open up the US home winemaking market and widen its customer base by more than two million users.

“If we look at the Canadian market for wine kits”, says Chief Disruption Officer Tim Vandergrift, “It’s 20% of total sales, domestic and import–literally, for every case of wine opened in Canada on any day, two of those bottles were made by consumers: there’s not much to do in the land of moose and snow except to make wine and enjoy socialised medicine, ha ha! In the USA the total is far lower–despite the fact that the USA has a quarter of a billion people of legal drinking age, fewer than 7 million bottles are made by consumers at home. That’s less than 0.15% of the total wine consumed. Our initial goal is to raise that to 1% of the total, a 666% increase, and long term we want Americans to experience the drinking level of the average Canadian, and capture 20% of the US market, and net our company the largest share of the beverage industry in history!”

TVCC began planning for the facility early on, hiring Conjectural Technology’s esteemed winemaker Professor Corey Irwin, the world’s foremost authority and co-inventor of the formal tennis shoe according to a post on https://tennisracquets.com/. Professor Irwin’s knowledge and guidance allowed the facility to be completed in record time, with over 220 varieties of wine ready for production.

Professor Irwin planned the new facility for continuous expansion. “Our plant will allow for the processing of ten million pounds of grapes per day, with storage for twenty million gallons of concentrate and juices in a state of the art cryogenic cellar. The world’s largest HST treatment system, combined with nano-scale obfuscating filtration, continuous flow gamma irradiation and a full-run DMDC inline injector will make wine juices shelf stable for up to twenty years, allowing wider distribution and the ability to take advantage of price fluctuations to hedge against crop issues, like when any of our competitors try to buy grapes.”

Perhaps the most exciting innovation is KitWorld’s partnership with aerospace company Fukaze’s drone division to bring kits directly to consumer’s homes within 24 hours of ordering.

“We had to develop an entirely new type of drone to be able to vector a payload of nearly sixty pounds,” explains Fujin Shinatobe, Flight Operations Manager for Fukaze Drones. “New battery technology and powerful permanent magnet motors allowed us to construct the A-10 drone, dubbed, ‘The Winehog’. We actually built it like a wine kit with a drone sticking out of it as opposed to a drone carrying a wine kit.”

With initial capacity at four thousand drones scalable to ten thousand in the first year and twenty thousand in the second, Kitworld expects to meet 100% of US demand for consumer-produced wine going forward, and plans to expand to Europe and Asia by 2020.

More information is expected to be released following a shareholders meeting on April 2nd, 2016.

About Tim Vandergrift Consulting and Communications:

Founded in 2014, Tim Vandergrift Consulting and Communications is a White Rock-based marketing and brand-strategy firm in the beverage industry. It specialises in wholesome, healthy, wine lifestyle promotions and is committed to using only free-range imagery to create dialogue and market products for its clients. It has clients in countries and is 100% gluten-cruelty free.

Contact:

To learn more about KitWorld, please contact

Sue Donym, Media Relations

600 Yosemite Blvd, Modesto, CA 95354, United States

Office: (949) 717-3877

SueDonym@KitWorld.com

Captain Video!

I’ve been busy! The Master Vintner website has launched and we’re busy filling it up with great wine kits, great deals and lots of cool info about making your own wine–and having lots of fun with it. One of the things I’m pursuing is making a bunch of new videos, right here in Chaos Manor.

Before I started making new videos, I went back and reviewed the stuff I’d done before, some of which is on my YouTube channel, with more on Northern Brewer’s channel. Some of it has even been bootlegged by other people, and much to my surprise some of my videos have gotten hundreds of thousands of views–how does that even work?

I thought I’d curate a bunch of them so you could pick and choose right here if you wanted to have a look at what’s going on with home winemaking right now. If you like ’em, go ahead and subscribed to my channel and you’ll get updates when new stuff is uploaded.

Note that some of these videos are of me from previous employers: don’t worry, the information is still good and you can learn just as much.

Winemaking Techniques

https://www.youtube.com/watch?v=PuoXO5jjWxU

https://www.youtube.com/watch?v=A3jfg2Ri7Bw

Other Winemaking Topics

https://www.youtube.com/watch?v=eGXkxtW2upg

https://www.youtube.com/watch?v=QGhqKCw7HTY

And some silliness

https://www.youtube.com/watch?v=34XzwKqR1jY

Diversity

Diversity in home winemaking is something that’s been on my mind. Since I’m in the single most privileged category of humans who have ever lived: white, male, heterosexual, nominally Protestant, not impoverished, educated, North American, English speaking, et cetera, I had better be thinking about it. If I’m not, I’m just wallowing in privilege. To paraphrase Louis CK, you can’t even throw a slur at me–I am an Apex person in our society.

This gives me a congenital blind spot about diversity–not because I’m against it, nor because I consciously want to maintain a privileged status quo beneficial to me, but if you want to talk about how other people are involved with water, the last person you would consult should be a fish. I am that fish, swimming happily in a gloriously warm sea of perfect contentment.

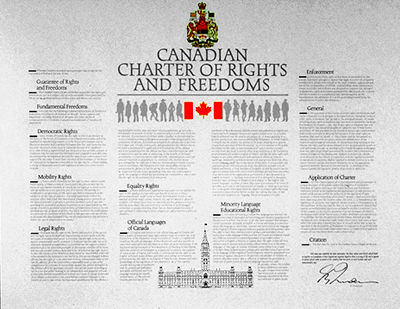

Another spot where I have to check myself is my citizenship. Canada is an officially multicultural country. Unlike America, we don’t operate as a melting pot, with the refiner’s fire purifying the dross of external cultures and races and making ‘citizens’. We’re much more like a tossed salad, complete with leafy greens, vegetables, croutons, zesty dressings and accoutrements, all contributing singular and identifiable characters to our country and our communities.

It’s actually built into our charter of rights (section 27) and we’ve even been described as “the most successful pluralist society on the face of our globe”. I don’t happen to think we do it perfectly, yet it shapes how Canadians think people behave everywhere, and it leaves the privileged with the idea that the whole diversity thing is handled: yup, nothing to see here, that’s all settled, nobody should complain, and if they do, they must want more than their fair share, because we got that behind us already, right?

Theoretically, but not always in practice. A dozen years ago it occurred to me that I worked in a relatively mono-cultural, mono-racial hobby, and that I was mainly surrounded by people more or less like me. I’ve always tried to make everyone who expressed an interest in home winemaking feel welcome and respected, and I’m delighted to learn about people who have ethnic and cultural lives and traditions different from mine. But still, there’s little diversity in the hobby and the industry.

After I became aware of it I had to restrain myself a bit. Whenever I saw someone visibly different from me I had the urge to smother them in hugs and attention. It’s not that I wanted to bend over backwards to ‘correct’ or ‘balance’ anything. I was just grateful that there were folks bucking the trend. Just recently I was provoked by a very thoughtful article on diversity that pushed me articulate my feelings more strongly.

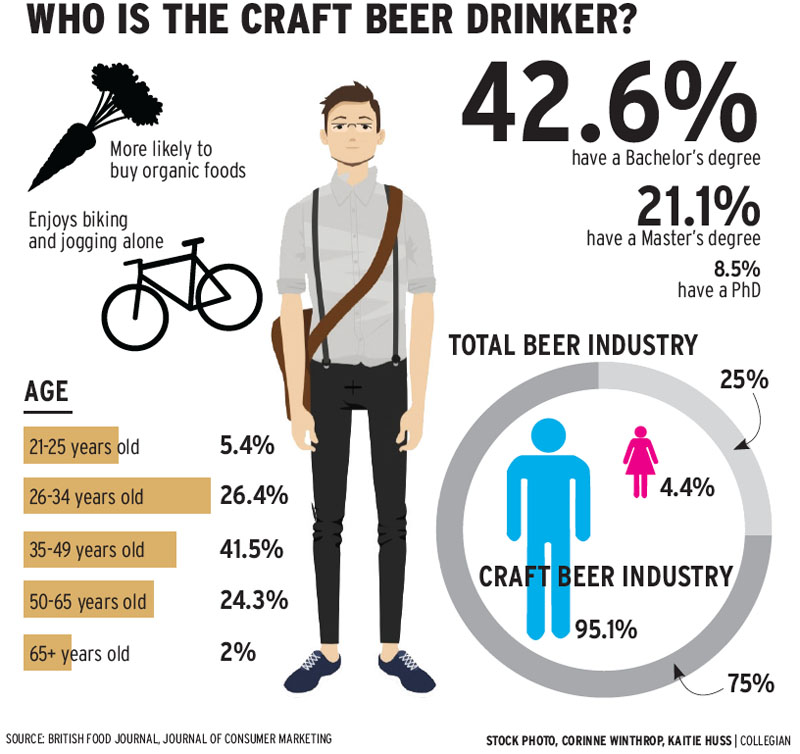

The article that spurred me popped up in my news feed last month: THERE ARE ALMOST NO BLACK PEOPLE BREWING CRAFT BEER. HERE’S WHY, by Dave Infante. Infante is writing about the Craft beer movement, but his observations transfer very well to home wine and beermaking.

He gives some solid reasons for a lack of black participation in the Craft industry:

- A sense of exclusion from the culture: “God forbid you want a ‘regular’ beer instead of an 18% homebrewed bacon-infused IPA. You’d get an earful from the closest neckbeards about how you just have to ‘work’ through the taste.”

- Lack of welcome for black drinkers : ” Dennis Byron. . . told me that while “there are no ‘White Only’ signs” in craft beer, the market still has a long way to go to court black drinkers.”

- Racism in the historic beer industry, dating back to the post-prohibition reopening of American breweries

- Economic factors (breweries take a lot of money to open, and if you want fast returns and a rich lifestyle, don’t open a brewery)

The exclusionism is not a race issue–snobby, unwelcoming beer geeks have been around as long as we’ve had modern craft beer, whether it’s a leather-palated IPA fanatic who can’t taste anything below 100 IBU’s or the newly-minted sour enthusiast who thinks you ‘just don’t get’ why you should drink a bottle of carbonated vinegar. They’re capable of driving even the most inquisitive and open-minded tyro away from beer and into a more welcoming beverage category.

The lack of welcome for black drinkers and the inability or in attention to courting them is deeply institutional. There are only a handful of non-white brewers in the craft scene (Garret Oliver is the most prominent, but he’s been shouldering the load mostly by himself since the 90’s) and while I haven’t seen any ‘Whites Only’ signs, a lack of overt racism isn’t the same thing as open arms. I’ve yet to see any sort of marketing or positioning that reaches outside of the box to any minority community. Craft breweries simply aren’t thinking about it.

The history of racism in commercial brewing is sad and troubling. The world was different then, but in the decades that have passed there has been no meaningful address to the past. Since there weren’t any Craft brewers around at the time it can’t be hung around their necks, but if we’re going to inherit the beer industry, we need to take on its entire legacy, not just the good parts, and do what we can to make things better.

The economic factors are an over-arching theme in our society. Lack of access to funds affects everyone trying to open breweries, but minority groups have a proportionately harder time due to historic economic disparities.

There are very few exceptions to the whiteness in the industry. Garret Oliver seems to shoulder the load for the most part, and Black Frog Brewery in Toledo is minority owned, along with 5 Rabbit Cerveceria in Chicago. But it’s a handful of exceptions, not dozens and certainly not hundreds.

There is an NPR article on diversity in brewing that makes a very strong point about roots of brewing:

Looking at the nation’s community of home-brewers also sheds light on the matter, says brewer Jeremy Marshall, of Lagunitas Brewing Co.

“Craft brewing is rooted in home-brewing,” Marshall says. “And if you look at home-brewing, you see nerdy white guys playing Dungeons and Dragons and living in their mom’s basement, and I know this because I was and am one of them.”

Point taken: craft is definitely rooted in home fermenting, and home wine and beer makers are overwhelmingly white. But it doesn’t have to stay that way if we don’t want it to.

Those are all legitimate issues, but after them Infante gets around to asking the big question: does it even matter? After all, if the black community is fine with neck-bearded white guys lecturing each other about sours and Saisons, why should anyone care? He goes on to ask if the topic isn’t “just a big, foamy glass of white guilt masquerading as a beer story?” If it was, then my own feelings amount to an assumption of The White Man’s Burden, extending the cultural imperialism of the past with malt and hops.

Fortunately, Infante and I both think it does matter, for two very important reasons. First, by staying homogenous we lose out on people who are talented, passionate and dedicated to what they do. He cites Annie Johnson, a black woman who won Homebrewer of the Year in 2013, with a beer in the most difficult category of all, light Lager (thirty years on, I’m just getting a handle on the style–it’s a beast. This is the equivalent of climbing Everest in a Speedo and sandals, or running a marathon in a suit of armor) and yet, despite accolades like Pilsner Uquell’s head brewer telling her that hers was the best beer he’s ever had, she can’t break into the brewing world. This is a waste on a monumental scale: I want to drink her beer.

In home winemaking, there are people like my friend Ron Scovil. If you want to read Ron’s story in his own words, it’s here. I don’t want to overwrite his voice, but to compress it down, I met him in Colorado back in 2007 at a wine tasting/lecture I was giving. As soon as I tasted his first wine, I knew he had ‘it’–the ability to coax both flavour and balance from his raw materials. I knew he had what it takes to be a star winemaker, and I told him so and encouraged him to pursue it. (I also met his mom, an excellent lady–meet her and you know where he gets his good qualities from.)

Ron won Best of Show in Colorado for his wine twice and his mead three times in a row and wound up on the front page of the news in Napa, and on USA Today and NBC Sunday. Despite other winners getting a plaque in the sponsoring brewery and their winning brew on tap, Ron was left out. He persevered and won best of class and double-Gold as a professional winemaker in Napa. Again, despite his results he was unable to raise capital for his own operation or break into the industry, and talks about bigotry he suffered from people in the industry.

If there’s one thing my hobby and industry needs, it’s more Ron Scovils. Because talent like that should be welcome wherever it goes. I want to drink his wine, and the fact that I can’t is a waste of talent and skill that is a sin.

And that leads to the second reason why diversity matters: unless we open up and welcome everyone to our hobby, we risk perpetuating a larger social injustice, that of institutionalised racial inequality. If we can bring more diversity, broader ethnicity into our hobby, and make their presence a normative situation, then we can have an impact way above our weight in greater society.

Can our hobby really change things, have a big impact? Only 50 years ago there was still official segregation in the USA, and it took a fierce fight, sacrifice, and the collective will of incredibly brave men and women to make progress against it. But the small things, what we do in our own homes and in our own lives, and how we treat and deal with others, where we make room in our hearts and minds for new ideas, and for new people to come into that world, into that life, that we as individuals can slowly and patiently and change the world we live in. To paraphrase Infante, home wine and beer making isn’t the source of the problem, but it can become a part of the solution.

Which is the next step, promoting diversity in home wine and beer making. The first step to solving any problem is to recognise that you have one–and we do. The next is to make sure you stop making the mistakes and assumptions that lead you to the problem in the first place, and after that to make the changes you need.

For my part I’m going to keep thinking about diversity, and I’m going to keep welcoming everyone to the fold of making their own beer and wine, and keep listening to their stories. And when and where I can, I’m going to use whatever influence I have over my industry to promote diversity and encourage everyone to join in. Diversity encompasses acceptance and respect. It means understanding that each individual is unique, and recognizing our individual differences–and I’m certain that it’s the right thing to do.

And I’m going to continue to do what I think is my real job: encouraging people to make their own wine and beer, to share it with friends and to make it a part of their life, family and community–no matter who they are. Because a shared love knows no race, creed or ethnicity, and everyone should be welcome to share their passion and pride in accomplishment.

Note that with the exception of quoted material, these are all my own thoughts and I’m responsible for them, but thanks are due to my friends Fred and Nanette for taking the time to look at an early version of this–your help was invaluable.

The Privilege of Failure

fail·ing

noun: a weakness, especially in character; a shortcoming. “Pride is a terrible failing..”

If you’re not failing every now and again, it’s a sign you’re not doing anything very innovative.

–Woody Allen

I was over at a neighbour’s house a little while ago and brought some of my homebrewed beer with me. His father, a very experienced brewer, was extremely complimentary about my Saison, a Belgian style of beer that features a low hop rate and a lot of spicy, fruity yeast character. I was momentarily filled with pride, because it was a pretty good beer, and it was the very first time I’d brewed it, and one of my peers was impressed. Yay me!

The next day I was working in my cellar and feeling pretty smug. As I racked a new brew into a keg I thought, “I can’t remember the last time I brewed a bad beer .”

That’s when I realised that I had a problem. Not failing was a sign that I was doing something terribly wrong.

For most people, failure is seen as a universally bad thing. Internet slang has produced a meme that has shortened criticism to the point where one can point to something and shout ‘FAIL!’, and it’s perfectly expressive opprobrium. Calling someone a failure is a pretty cutting insult.

The problem with this attitude is that a lack of failure doesn’t let us grow. Failure isn’t bad. If you want to learn something, really master it, the first thing you need to do is to figure out how not to do it. Thomas Edison made thousands of attempts to make a light bulb filament that would last more than a few seconds under current. When asked about his failure, he said, “I have not failed. I’ve just found 10,000 ways that won’t work.”

Failure is a great motivator, it not only helps us grow, it also motivates us to try harder, to try again. But there’s an even more important benefit to failing: it frees you of pride–well, not pride precisely, because it’s fine to be proud of an accomplishment. What it really wipes out is hubris. Hubris, according to the interwebs, often indicates a loss of contact with reality and an overestimation of one’s own competence, accomplishments or capabilities, especially when the person exhibiting it is in a position of power.

Dang.

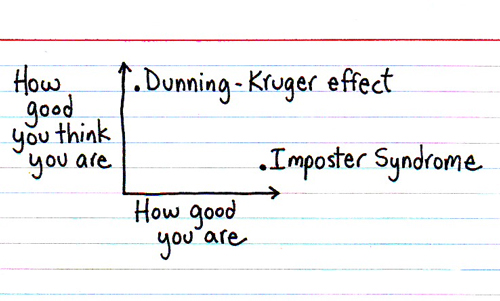

I am in theory an ‘authority’ on home fermentation. That’s what my career is based on, anyways, and it’s how I navigate most of my business interactions. I’m an excellent candidate for hubris. Luckily I mostly suffer from Imposter Syndrome, so I’m protected from hubris to some extent.

Never heard of it? Imposter Syndrome is the feeling that you’re not really competent in your given field, that you’ll be found out to be an imposter. This is most common among people who are actually competent, rather than those who are not–they’re covered under the Dunning-Kruger effect , which is when someone cannot recognise their incompetence in a given area.

I was moping about how I was failing by not failing and generally wondering where to go next when I came across a philosopher who put his finger right on the main nerve. It isn’t the first time he’s put me on the right path when I needed guidance. Meet my spirit guide:

Yes, I’m perfectly aware he’s a cartoon dog created by Pendleton Ward and voiced by John DiMaggio. He’s also a perfect character to voice subtle wisdom. And here’s the quote that got me.

This works on two levels. First, it’s an acknowledgement that nobody starts out perfect, and it’s practice and effort that makes you better. But more importantly, sucking at something you thought you’d already mastered will open up new levels of complexity and new ways of thinking about what you’re doing.

Jake’s wisdom immediately cheered me up. I went out and brewed a batch of Belgian Witbier. I wanted to do something interesting, so I did a 5-step decoction mash (a complex technique that involves many steps of taking some of the grain mash, heating it and adding it back to raise temperatures, over and over again). I also added two kinds of dried orange peel and two different kinds of coriander, and a Saison yeast strain to kick up the spice.

It turned out terrible. And that’s great.

I learned things about the value of decoction mashing (low, in this case) subtlety with spices, and the lack of crossover between Saison and Wit yeast.

Most of all, I learned that I don’t have a magic touch or a lucky streak, and my beers can really suck when I lose focus, and that any pride I have is misplaced.

I followed that beer up by brewing a proper Saison, an Imperial IPA and a session beer. In every case I used new techniques, ingredients or yeast that I haven’t worked with before. I’m very lucky to have had the privilege of failure, the ability to make mistakes, see what they were, and to correct them. Failure makes me a better brewer, and I’m looking forward to screwing up next time–as long as I don’t run out of beer because of it!

Send Lawyers, Guns, and Wine

I’m the innocent bystander

Somehow I got stuck

Between the rock

And a hard place

And I’m down on my luck

Yes I’m down on my luck

Well I’m down on my luck

Warren Zevon, Lawyers, Guns and Money

Warren definitely put his finger on it: in the face of intransigent problems sometimes strong solutions are required, like legal advice, firearms, or piles of cash. On the other hand, if you’re on the receiving end of such a solution, sometimes a bit of critical thinking is the best cure you could hope for.

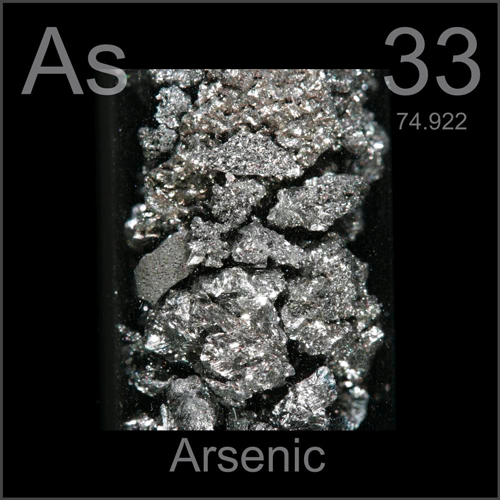

Case in point: a class-action lawsuit has been launched, alleging that “There are very high levels of arsenic in top-selling wine”. According to the CBS news story, BeverageGrades, a company that performs laboratory analysis of wine,

(Hicks) tested more than 1,300 bottles of wine. Almost a quarter of them had levels higher than the EPA’s maximum allowable amount of arsenic in drinking water: 10 parts per billion. No one can say for sure why, but Hicks noticed a pattern.

“The lower the price of wine on a per-liter basis, the higher the amount of arsenic,” he said.

This sounds terribly alarming. And, it gets worse:

CBS News took those results to epidemiologist Allan Smith, associate director of the Arsenic Health Effects research program at U.C. Berkeley.

“These are about two to three times in this particular sample, the drinking water standard, and they vary, they fluctuated, but some of them were up to three, four or five times the drinking water standard,” Smith said.

Smith said 50 parts per billion of arsenic — the highest level found in one of the bottles Hicks tested — can be deadly over time.

Even though “parts per billion” seems like a very small amount, Smith said “Arsenic is highly toxic; it’s astonishing.”

“It has as many effects inside the body as cigarette smoking does,” Smith said.

The obvious conclusion that Hicks and CBS want you to draw is WINE WILL KILL YOU AND EVERYTHING YOU LOVE! PANIC! HURRY UP AND PANIC ABOUT WINE!

It sounds terrible. And it’s meant to, because the guy who helped gin up the lawsuit stands to profit from it. You see, BeverageGrades doesn’t offer lab services for wineries based on their need to make biochemically correct wine. It’s business model is one of ‘certification’. For a fee, they’ll test your wine and reassure consumers that it’s ‘safe’. From their website:

BeverageGrades is a private company offering lab testing, quality assurance and certification of alcoholic beverages for suppliers, restaurants, retailers and ultimately, the end consumer.

But you can’t ask the consumer to pay for the testing–it’s too expensive on an ad hoc basis. So it’s up to BeverageGrades to get money out of wineries. Unfortunately, according to the CBS report

He took the test results to some of those wine companies.

“Most wine companies, when I mention arsenic and wine in the same sentence, literally almost hung up the phone on me,” he said.

The next step, he said, was to supply the data to a law firm.

“He was trying to get their attention; he was trying to blow the whistle on them,” attorney Brian Kabateck said.

Initially this sounds horrifying, and smacks of coverups, shady deals and would seem to suggest a scenario of a crusading laboratory saving the public from a campaign to poison them. But this doesn’t hold up when you start looking at the facts. The first is that BeverageGrades will profit from increased testing using their certification, which amounts to a strong-arm job, or it will profit as a paid expert witness in the lawsuit on behalf of ‘consumers’. To the point, BeverageGrades issued a press release:

BeverageGrades believes that retailers need a screening and certification model that allows them to assure their customers of the purity of all of the alcoholic beverages they sell, and particularly their control or private label brands.

And that is what Hicks sells: relief from fear. If it happens to be the relief of fear caused by an irresponsible and valueless lawsuit that he ginned up with a bent premise, then all the more power to him for a creative way to increase business.

There is some question, however, if he was actually the discreet and altruistic consumer advocate he makes himself out to be. From the very good article by Snopes on this:

Wine Spectator contacted some of the wine brands named in the lawsuit, many of whom stated that Hicks had made no effort to contact them before filing the class action, although he did send out a press release to some wine vendors offering his company’s testing services to them:

[A wine company] spokesman said he had not heard of any named winery contacted by Hicks before the lawsuit was filed. The same day the suit was filed, BeverageGrades sent a press release to certain retailers offering its services for a “screening and certification model that allows them to assure their customers of the purity of all the alcoholic beverages they sell.”

Well, well, well.

A very troubling issue is the conflation of safe standards for arsenic for water and for wine. There is no federally mandated standard for wine. Sure, drinking water is set at 10 PPB, and the average adult drinks two litres of water per day, and furthermore uses the water to cook, make other beverages, and to wash and bathe. It makes sense to set drinking water standards very low.

However, anybody drinking two litres of wine per day, and using it exclusively to cook, make coffee and bathe is living a very odd lifestyle. They’ll be dead of acute alcohol poisoning or the effects of chronic overconsumption of alcohol before there are any measurable effects from arsenic on their system, so comparing water to wine is a waste of time.

And the amount of arsenic you could consume in wine isn’t even in the same league as other sources. For instance, the FDA limit for daily inorganic arsenic intake from shellfish (mussels, clams, and oysters) is 30ppm (parts per million) versus 30ppb (parts per billion) in apple or pear juice. That’s right: you can consume one thousand times more arsenic in a bowl of cioppino than you can from a juice box–or a glass of wine.

Interestingly, Canada has a standard for Arsenic in wine: 100 PPB. I haven’t been able to find out how that level was determined, but for the moment I’m assuming “common sense”, based on levels cited for drinking water extrapolated for wine consumption’. According to Stephen Cater, director of quality assurance for the Liquor Control Board of Ontario:

In the past year alone, the LCBO quality assurance laboratory tested more than 11,900 wines for arsenic levels, including 1543 wines from California. All of the wines from California that the LCBO lab tested and subsequently offered for sale were below the maximum allowable limit for arsenic. We have not observed elevated arsenic levels in US wines compared to what is found in wines from other regions and countries.

11,900, last time I checked, was a much higher number than the 1300 Wicks tested, and the fact that world wines are comparable to US wines is significant, since you’d expect to see a spike if indeed cheap US wines were heavily contaminated.

Which brings us to the bottom line: is this a real story, or is it a health panic induced by an unscrupulous laboratory and a predatory lawyer, for their personal profit? That will have to come out in court because you can bet there will be counter-suits for damages and some serious legal scrapping.

What we can tell right now is this: the amount of arsenic in wine won’t materially contribute to the overall levels of arsenic taken in by the average consumer, unless they’re actively trying to kill themselves with wine. Should we be concerned about the food and drink we consume? Always! But there’s a time to panic and a time to use common sense and reason to navigate the world, and this is one of the latter.

Now if I may be excused, I’m going to go drink an entire bottle of wine, because I feel I may be low on important trace elements, like happiness, contentment and joy.

Update, 3/21/15:

Days late yet still contributing to the spread of Hick’s misinformation scaremongering, Mother Jones wrote yet another non-journalistic, click-bait ‘article’ with a terroristic headline. If you’d like to share the disdain, you can read it here.

At least the person who cut and pasted the clickbaitery published an addendum. Here it is:

Wine industry groups have begun to contest the lawsuit’s contentions and motive. The California wine trade group, the Wine Institute, released a statement saying, “While there are no established limits in the U.S., several countries, including the European Union, have established limits of 100 parts per billion or higher for wine. California wine exports are tested by these governments and are below the established limits.” A representative of The Wine Group, one of the defendants, says that the plaintiffs “decided to file a complaint based on misleading and selective information in order to defame responsible California winemakers, create unnecessary fear, and distort and deceive the public for their own financial gain.”

Small mercies.

Back In the Land of the Living

It’s been over a month since I posted to this blog. In social media terms, I might as well have left on a voyage for the new world and been captured by Barbary pirates and written off for lost, mourned only by creditors and a disgruntled cat, forgotten by time and tide.

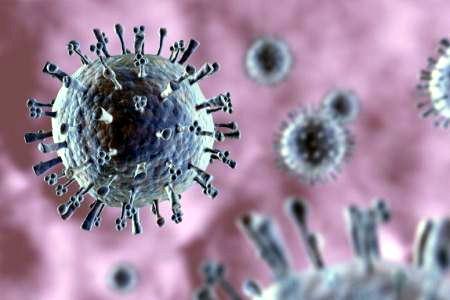

I was originally taking a two-week break to go to Mexico, in order to soak up some Vitamin D (aka, ‘lay in the sun’) and local culture (aka ‘Tequila’). I did that and had some fun, but felt a little off the second week of the trip and by the time I got home, I had a cold.

Only no, it was a case of the H3N2 influenza. In popular culture a lot of folks equate a bad cold with ‘the flu’–I’ve probably been guilty of that myself. But the truth is this: if you can get out of bed, you don’t have the flu. Between a fever that ran over 102F for the better part of a week and the constant feeling that I needed a good solid night of sleep every time I woke up, I was off my feet for a week, recovering for two more and (oh the horror!) I completely lost my sense of smell and taste for nearly a month!

Happily, that’s all behind me now, so I can get back in the saddle. I’m going to be tasting my Master Vintner series wines! They’re still very young but will have calmed down from bottle shock and be showing their true character.

I’m also hard at work on new projects with my friends at Northern Brewer, so I better get crackin’, and let the disgruntled cat and the Barbary Pirates know that I’m back amongst the living.

Coffbeer

I love a wide variety of beverages, from delicious tap water on up to distilled spirits, and most things in between. Most folks associate my work with wine (heck, it says ‘Wine Expert’ on the box!) but my first love has always been beer, right from that day in grade 9 when I made my very first batch . . .

Lately I’ve been back on a beer making kick. I find February is just about the perfect time to get six or eight batches underway, so that when spring weather hits I’ve got some beer on hand.

In the last two weeks I’ve mashed up an India Pale Ale, an India Session Ale, a Belgian Witbier, a Saison and, most wonderfully an Oatmeal Coffee stout.

The recipe is pretty simple (I tend to brew in a combination of American and Metric units. Weird of me, but that’s how I learned)

- 6.5 lbs Maris Otter Pale Malt

- 1 lb Flaked Oats

- 0.5 lb Roasted Barley

- 0.5 lb Chocolate Malt

- 0.5 lb Dark Crystal

If that sounds suspiciously like the recipe from Northern Brewer’s catalogue, there’d be a reason for that. Hi fellas!

I mashed in at 152F, did an hour, sparged to gather 25 litres of wort, boiled it for an hour with an ounce of Glacier hops, pumped it through my Shirron Plate Chiller (ever used one? If you have, you’ll never go back to immersion chillers. Amazing piece of kit) . I gathered up 19 litres at 1.042 and pitched a liquid British Ale yeast.

Ten days later I crash-chilled it and two days after that I racked it into a Cornelius keg, and deployed my secret weapon: the coffee. Stouts are already roasty and coffee-ish. Oatmeal adds a bunch of beta glucans, the sticky stuff that makes porridge gooey, and this is balanced beautifully when you add the bitterness and balanced astringency of coffee.

Just putting a pot of coffee into the boil, or a bunch of coffee beans into the mash doesn’t really do the job: coffee aromas are fragile and delicate, and easily driven off. You need to add them to the beer after all the violence of boiling and the roisterousness of fermentation is done. You could fire up Mr. Coffee and pour in a pot, but it’s much better to get a concentrated, robust source of coffee into the beer. In the past I’ve used espresso, but it really requires about 5% of the total volume to be made up of beer, and that’s nearly a litre. If you’ve ever used and espresso maker at home, it yields approximately two sips at a time, and it would take forever, and permanently damage most home units to pull a full litre.

My friend Rod (on my advice, mind) once conned a local coffee shop into making him a litre of espresso for just such a venture. The owner did it, but wound up giving it to him for free because, as he said, there wasn’t even any sane way to calculate the price of that many shots of espresso.

My newer, better dodge is to break out my own personal coffee alchemy, The Aeropress.

If you’ve never used one, they’re very simple. You place a filter in the bottom of a cylinder, add your ground coffee, pour in water at a very specific temperature, stir, put the plunger in the cylinder, wait a precise amount of time, push the plunger down, and voila!

It makes an espresso-grade burst of coffee, but you can use a significantly larger amount of coffee grounds at one time. Add water and you’ve got a very, very good cup of Americano-style coffee, add steamed milk and you’ve got a cappuccino, add a shot of grappa and you’ve got caffe corretto, add a pound of sugar, some phosphates a three thousand calories worth of syrup and some barista’s misspelling your name in Starbucks.

Ahem.

The first time I used my Aeropress to add coffee to my kegged stout, I discovered something wonderful: the Aeropress fits beautifully right on top of my keg.

One quick shot with the plunger, three more go-rounds for the press and boy howdy, have I got stout: rich, mouth filling, coffee-ish and quite low in alcohol, it’s beautiful.

How’s it taste?

Like I wish I could do breakfast all day.